Introduction — why maintenance matters

An electric fence is only as good as its upkeep. In Kenya, fences protect livelihoods — crops, livestock, homes and wildlife. When a fence fails it’s usually not the energizer that’s to blame but something simple: overgrown vegetation, loose connections, corroded clamps, or broken insulators. Regular maintenance reduces downtime, lowers long-term cost, and prevents losses from theft, predation, or crop raids.

A well-maintained fence also extends the life of energizers, batteries, and posts. Preventative care is far cheaper than emergency repairs. This guide gives Kenyan farmers, estate managers, and conservancy teams everything they need to keep fences working: inspection schedules, troubleshooting flows, toolkits, parts lists, cost estimates, contracts, and real examples from Kenyan farms and estates.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

What good maintenance achieves

Routine maintenance keeps voltage consistent, reduces false alarms, prevents energizer burnout, and ensures legal and safety compliance. It increases deterrence value (intruders are less likely to test a reliably hot fence), decreases livestock escapes, and supports tourism and conservancy goals by reducing human–wildlife conflict. With regular checks you catch problems early — a snapped insulator or corroded clamp — before they cause a total line failure.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Who should maintain electric fences

Maintenance can be done by trained farm staff for routine tasks and by professional technicians for commissioning, major repairs, and diagnostic work. Smaller farms can train one caretaker; larger farms, estates and conservancies often have a dedicated fencing team and a service contract with a specialist. For community fences, appoint an operations committee and rotate caretaking duties.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Overview of typical maintenance tasks

Maintenance tasks range from daily visual checks to annual professional servicing. They include cutting vegetation, checking voltages, tightening tension, replacing insulators, inspecting earth rods, cleaning battery connections, checking solar panels, and protecting the energizer from surges and moisture. The guide below breaks tasks into weekly, monthly, quarterly and annual timetables, and gives how-to steps for each.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Tools and spares every fence caretaker needs

A compact kit saves hours. Essential tools:

-

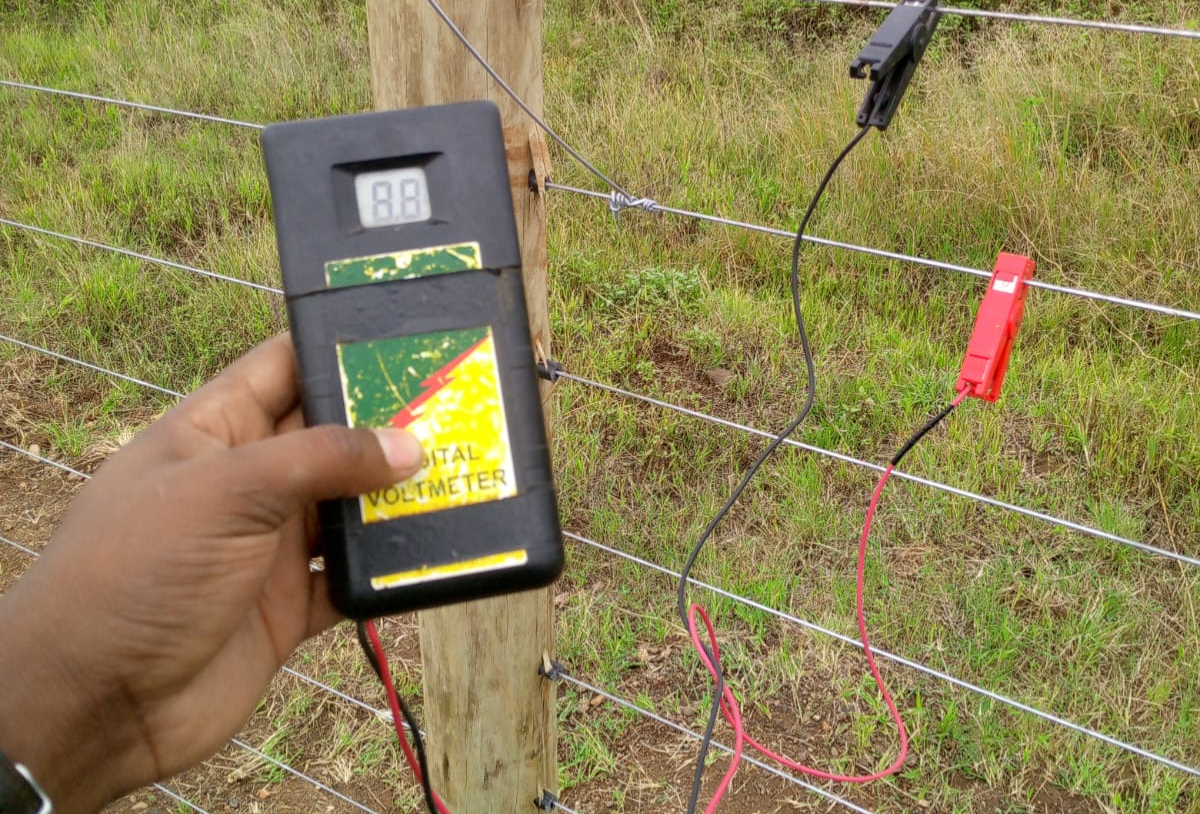

Digital fence voltmeter (Gallagher DVM or similar)

-

Directional fault finder (JVA/Nemtek/Stafix style)

-

Insulated pliers, wire cutters, long-nosed pliers

-

Spare insulators (clip-on and screw-in), clamps, gate isolators

-

Spare fuses, earth clamps, stainless-steel bolts, washers

-

Small roll of high-tensile wire and polytape, tensioning tool (ratchet strainer)

-

Multimeter, screwdriver set, spare battery for voltmeter

-

Earthing rod driver and spare earth rods

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Weekly maintenance checklist (what to do and how)

-

Visual walk: Check entire perimeter for fallen trees, animal damage, or cut wires.

-

Voltage spot checks: Use a DVM at energizer, mid-line, and far end. Record values.

-

Vegetation: Cut grass and branches touching wires or within a 1m corridor.

-

Insulators: Look for cracked or brittle insulators and replace.

-

Gates: Confirm gate isolators work and that gate hinges are secure.

Tips: Record findings in a logbook. If you see a sharp voltage drop between two points, mark and continue the walk — a detailed fault hunt comes next.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Monthly maintenance checklist (deeper checks)

-

Full voltage profile: Walk and record voltages every 200–500m to spot degrading sections.

-

Tension check: Re-tension wires where sag exceeds acceptable limits.

-

Earthing: Test earth rod resistance; in dry seasons add more rods or dig deeper.

-

Battery care: For battery-backed systems check electrolyte (lead-acid) or SOC (lithium) and clean terminals.

-

Solar panels: Clean panels and inspect mounts; check controller and wiring.

If you find localised low voltage, use a directional fault finder to locate the leak or short. Keep a spare battery and a portable solar charger if remote.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Quarterly and annual servicing (professional tasks)

Quarterly: check energizer internals for corrosion, test lightning protection blocks, inspect major clamps and replace worn fittings.

Annually: full energizer service — capacitors, PCB checks, full load testing, firmware updates for smart units, replace deteriorated earth rods, and load testing of fence under normal vegetation load. A professional installer should perform annual servicing and provide a commissioning report.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Common failure modes and how to fix them (step-by-step)

Problem: Low or zero voltage at far end

-

Likely causes: vegetation contact, broken wire, poor earthing, loose clamp, or faulty energizer.

-

Fix sequence:

-

Check energizer output at terminals.

-

Walk line with DVM to find where voltage drops.

-

Use directional fault finder to locate short.

-

Clear vegetation and repair broken wires.

-

Improve earth connection if energizer terminal voltage is low.

-

Problem: Intermittent faults (works sometimes)

-

Likely causes: loose connectors, moisture in insulators, animal rubbing.

-

Fix: use directional finder during fault conditions, replace suspect connectors, dry and replace insulators; consider repositioning wires to reduce rubbing.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Fault-finding tools and how to use them

-

Digital voltmeter (DVM): measure volts quickly. At least three read points (near energizer, mid, and far).

-

Directional fault finder: shows direction and magnitude of leakage; walk the fence following the arrow.

-

Fault-finder remote kits: for compatible energizers they can remotely activate a pulse for testing.

-

Multimeter: for testing battery voltage and continuity.

-

Insulation resistance tester: for advanced testing to measure leakage across conductors and earth.

Using tools: always follow safety steps (isolate if needed, use insulated probes) and document readings to spot trend deterioration.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Insulators, clamps and connectors — common parts that fail

Insulators crack from UV, chalk under load, or are chewed by animals. Gate isolators and strain insulators often see the most stress. Stainless steel clamps are better than galvanized for longevity. Use tinned copper or stainless connectors for low corrosion. Replace cheap plastic insulators with UV-stabilized, high-impact versions when possible.

Inventory tip: keep a stock of 50–100 insulators, several strainers, a roll of wire and two clamps per kilometre of fence.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Caring for energizers, batteries and solar systems

Energizers should be mounted in dry, ventilated enclosures off the ground and away from animals. For battery backup:

-

Keep terminals clean and tight.

-

Check electrolyte level and specific gravity for flooded lead-acid batteries monthly.

-

Charge batteries properly and avoid deep discharges.

-

Use solar charge controllers to prevent overcharging.

For solar: clean panels monthly, inspect mounts and wiring, and ensure panels face the sun (usually north in Kenya) with a slight tilt. Protect batteries from extreme heat where possible.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Lightning and surge protection

Kenya has lightning-prone regions; spikes can destroy energizers. Fit lightning arrestors on the energizer ground and at strategic fence points, and install surge protection devices (SPDs) on mains lines. Regularly inspect arrestors after storms; replace any with visible arcing or damage. Consider a dedicated earth stake for surge protection separate from the fence earth if required by the energizer manual.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Seasonal considerations across Kenya

-

Dry season (Rift Valley, Kajiado) — earth rods are less effective; add rods or use longer rods and moisten earth contacts. Inspect for termite activity.

-

Wet season (Nyanza, Western) — vegetation grows fast; schedule extra cuts and check for short-circuiting from collapsed branches. Watch for water ingress into energizer cabinets.

-

Coastal areas (Mombasa) — corrosion risk is high; prefer stainless steel and frequent clamps checks.

Adapt the maintenance schedule and supplies to local climate.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Service contracts vs ad-hoc repairs — which suits you?

Service contracts are great for larger farms and estates: a monthly fee covers routine checks, minor repairs, spares, and emergency call-outs. Contracts ensure a known budget and rapid response. Ad-hoc repairs suit smallholders with local caretakers and a small stock of spares. For community fences, a mixed model (caretaker does weekly tasks; contracted team does quarterly servicing) often works best.

When choosing a contractor, check response times, spare parts availability, and ask for references. Contracts should specify SLA (response time), inclusions/exclusions, and liability for third-party damage.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Case study — a conservancy’s maintenance program in Laikipia

A mid-sized conservancy in Laikipia implemented a scheduled maintenance program after suffering repeated nighttime incursions. They contracted a local fencing company for quarterly professional checks and trained three rangers as caretakers for weekly tasks. Results:

-

Fence uptime increased from 70% to 98% within six months.

-

Ranger response time to alarms fell from 90 minutes to 15 minutes.

-

Poaching and crop-raiding incidents dropped sharply.

The conservancy credits routine earthing checks and immediate vegetation control as the two most important changes. They now budget maintenance into their annual plan.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Training caretakers — what they should know

Train caretakers to:

-

Safely take voltage readings and document them.

-

Use a directional fault finder and basic wire repair techniques.

-

Maintain batteries and solar panels (cleaning and basic checks).

-

Replace insulators and re-tension wires using ratchet strainers.

-

Follow safety protocols (isolate energizer for close work, use insulated tools).

A one-day practical training plus a toolbox talk every season is usually sufficient for most farms.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Safety, signage and legal compliance

Always place warning signs on electrified perimeters at regular intervals and at all gates and public crossings. Keep records of commissioning and annual servicing; insurers often require this documentation. For fences near public paths or schools, design safe crossing points and use insulated crossings or gates to prevent accidents. Follow county bylaws about fencing and public rights of way.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Upgrades and modernization — add telemetry and alarms

Consider remote telemetry (Cloud Routers, GSM alerts) if you manage large or remote fences. Telemetry warns you of voltage drops by SMS or app. Add alarmed gate isolators to notify guards when gates remain open. Smart energizers with built-in diagnostics reduce troubleshooting time and allow remote resets in some systems — ideal where technicians are not immediately available.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Final checklist before calling a technician

-

Have your maintenance log and recent voltage readings ready.

-

Note exact location of fault or last functioning point.

-

Confirm energizer model and power source.

-

Take photos of broken points or damaged insulators.

-

Make spare parts available (if you have them) to reduce call-out time.

Technicians appreciate preparedness — it reduces time on-site and cost.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

FAQs — quick answers

Q1: My fence trips only at night — why?

A: Moisture increases leakage at night; vegetation and animal activity also increase. Use a fault finder during a fault and clear vegetation.

Q2: How often should I replace earth rods?

A: Every 3–8 years depending on corrosion and soil. Test earth resistance annually.

Q3: Can I repair wires myself?

A: Small repairs are fine for trained caretakers. For energizer or complex faults, call a technician.

Q4: Is it safe to touch an electric fence?

A: A controlled electric fence delivers a deterrent shock. It is generally non-lethal, but avoid touching it and ensure signage.

Q5: My solar energizer isn’t charging well — what to check?

A: Clean panels, check controller settings, inspect battery terminals, and test panel output with a multimeter.

Q6: How much should I budget annually for maintenance?

A: Smallholders: KSh 20–60k; medium farms: KSh 60–200k; large conservancies: KSh 200k+. Budget depends on fence length, terrain, and tech levels.

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Conclusion — build maintenance into your fencing plan

Repair and maintenance are not optional — they are part of the fence. Treat your electric fence as a critical asset: schedule checks, keep spares, train caretakers, log readings and engage professional servicing. The result: fewer losses, lower long-term costs, and a fence that works when you need it most.

For professional maintenance, fault-finding, spare parts and service contracts across Kenya, contact:

Electric Fences Kenya Ltd — Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

Web: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

Electric Fence Maintenance SOP

Purpose: Fast-reference, printable SOP for routine care, fault-finding and emergency response for electric fences.

Scope: Applies to electric perimeter fences on farms, estates and conservancies in Kenya.

Safety First

- Assume fence is live unless isolated & tested.

- Wear insulated gloves and use insulated tools for repairs.

- Do not work on fence alone; have a colleague nearby when isolating power.

- Display warning signs at gates and public access points.

Contact & Escalation

- Electric Fences Kenya

- Call/Text/WhatsApp: +254 722 708034 / +254 720 456534

- Websites: www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa

- Emergency escalation: If major energizer fault or large structural damage, call above and note time & location.

Tools & Spares

- Digital fence voltmeter (DVM)

- Directional fault finder

- Insulated pliers, long-nose pliers, wire cutters

- Ratchet strainer & tensioning tool

- Spare insulators (clip/screw), stainless clamps, gate isolator

- Spare fuses, earth clamps, 5–10m spare wire, roll of polytape

- Multimeter, spare batteries, torch

- Maintenance logbook & marker

Weekly Checklist (Do every 7 days)

- Visual walk of full perimeter; note fallen trees, debris, animal damage.

- DVM voltage check: energizer terminal, mid-line, far end — record in log.

- Clear vegetation within 1m of fence line.

- Check gates & gate isolators; confirm functioning.

- Replace any obviously damaged insulators or clamps.

Record: Date | Time | Voltage readings (term/mid/end) | Issues found | Action taken | Technician

Monthly Checklist

- Full voltage profile every 200–500m; record values and compare to previous month.

- Tension check: re-tension wires where sagging > defined limit.

- Earth rods: inspect clamps & test resistance; add rods if resistance high.

- Battery check (if applicable): inspect terminals, electrolyte level or SOC.

- Clean solar panels and inspect mounts & wiring.

Quarterly Tasks

- Inspect energizer enclosure for moisture/corrosion; test alarm outputs.

- Test lightning arrestors and surge protection devices.

- Replace worn strainers, major clamps or degraded insulators.

- Review maintenance log for recurring faults and plan corrective works.

Annual Service

- Full energizer diagnostic and internal inspection (capacitors, PCB, fuses).

- Earth system re-test and replacement of compromised rods.

- Load-test fence under normal vegetation conditions.

- Firmware update / telemetry health-check (if applicable).

Emergency Fault Procedure (Fence down / No voltage)

- Note exact location and last known working point.

- Check energizer power source (mains, battery, solar). Ensure energizer is on.

- Measure energizer terminal voltage. If low, check batteries/charging.

- Walk line with DVM; where voltage drops sharply, mark spot.

- Use directional fault finder to pinpoint short and follow arrow to fault.

- Clear vegetation, repair broken wire or replace insulator/clamp.

- Re-test voltage; log actions and time to restore.

- If energizer shows internal failure, isolate and call service provider.

Common Quick Fixes (Do only if trained)

- Vegetation short: clear plants, retest.

- Broken wire: splice using approved clamp and tension; avoid staples piercing conductors.

- Loose clamp: re-tighten or replace with stainless clamp.

- Corroded terminal: disconnect, clean, apply anti-corrosion grease, retest.

Maintenance Log Template

- Date: ________ Time: ________

- Weather: ________

- Energizer model: ________

- Voltage @ Term: ______V Mid: ______V Far: ______V

- Issues found: ___________________________________________

- Action taken: _________________________________________

- Parts used: ___________________________________________

- Technician name & signature: ___________________________

Train two people on SOP and fault-finder use. Review SOP annually or after major incidents.

Prepared by: Electric Fences Kenya

Contact: +254 722 708034 / +254 720 456534 | www.electricfences.co.ke | www.electricfenceskenya.com | www.electricfences.africa